Bullet setback is an undesirable condition where mechanical forces acting on a loaded cartridge cause the bullet to be pressed back into the case; reducing the cartridge overall length (C.O.A.L.). Setback is most likely to occur when the bullet nose of a semi-auto pistol round strikes the barrel feed ramp while the cartridge is being chambered. The problem is compounded (especially with self defense 'carry' ammo) when the same round is chambered and rechambered multiple times as your pistol is loaded and unloaded.

Setback is undesirable because it causes a reduction in the available internal case volume, which results in higher-than-normal pressure when the round is fired. In extreme cases, a setback-induced pressure spike can exceed the safe limits for the cartridge. This is of particular concern with 'defensive' pistol calibers that push the pressure envelope, such as the .40 S&W.

This article describes some of the causes of setback, as well as ways to detect and avoid the problem.

Detecting Setback

One check you should be doing as part of your normal reloading process is something popularly called the "bench test" or "press test". It's

very simple: During setup, measure the overall length of one of your freshly loaded rounds, put your thumb on the case head and firmly press the nose

of the bullet into your bench, then re-measure the round. If the second measurement is shorter than the first, then your rounds are prone to setback.

The ultimate test for setback is to chamber a round in your pistol several times, checking the C.O.A.L. after each chambering. It is best to use a "dummy" round (no powder and primer) for this test. If you wish to use a live round, do it safely at the range.

A few thousandths of an inch of setback is normal, however, if the bullet sets back 0.010" or so all at once, you have a problem that probably needs correcting. If the setback progressively increases by a few thousandths of an inch each time you chamber the round, and you intend to use the ammo in your carry gun, you should take steps to avoid rechambering the same round multiple times. Some shooters "rotate" their ammo: Each time the pistol is unloaded, the magazine is unloaded as well, and the round from the chamber is placed at the bottom of the magazine. Others simply keep their carry gun loaded.

Possible Causes

There are several possible causes for setback. These should be checked and if necessary corrected. I'm going to list them in order

of likelihood.

Sizing Die is not set low enough

Most rimless pistol cases are tapered - some (like the 9mm) more than others. Many sizing dies are also tapered, and will properly size

only when the case is fully inserted into the die. If you leave too large of a gap between the shellholder and die, your cases will be

insufficiently sized, and prone to setback. Even a 1/16th" gap between the shellholder and die can result in setback for a rimless

straight-walled pistol caliber.

If you're using steel pistol dies (less common), ensure that the shellholder 'cams over' slightly when the ram is raised all the way up. If you're using a carbide sizing die (more common), ensure that there's a minimum amount of space between the shellholder and die when the ram is fully raised. The exact setup procedure for your dies can be found in the manufacturer's instructions.

Your expander die is optimized for a different bullet

The expander die in a three or four die pistol set performs two functions: It flares the mouth of the case to make it possible to seat a bullet,

and it expands the inside diameter of the top portion of the case to the proper size for the bullet. Some progressive presses (Dillon

for example) use a powder-through expander at the bottom of the powder measure instead of an expander die to perform these same tasks.

It's the second function (expansion) that can be troublesome with regards to setback.

Many reloaders are under the mistaken impression that all reloading die manufacturers adhere to some sort of standard, and that all dies are the same regardless of manufacturer. This is not true. Take expander dies for example (see Figure 2). These dies feature a mandrel that expands the inside diameter of the case, and an angled flaring shoulder that bells the case mouth.

The diameter of the mandrel varies slightly from manufacturer-to-manufacturer, as does the length of the mandrel, and the amount of taper at the end of the mandrel. The length and taper of the mandrel determine how much of the top of the case is expanded, while the diameter sets the amount of expansion.

In order to properly bell the case mouth, the mandrel must be inserted into the case, all the way up to the flaring shoulder. The length of the expander mandrel determines how much of the case is expanded, and it varies depending on who made the dies. Many of the expander mandrels' lengths correspond to the 'normal' bullet for a particular caliber. Hornady dies in particular tend to have longer mandrels than other manufacturers.

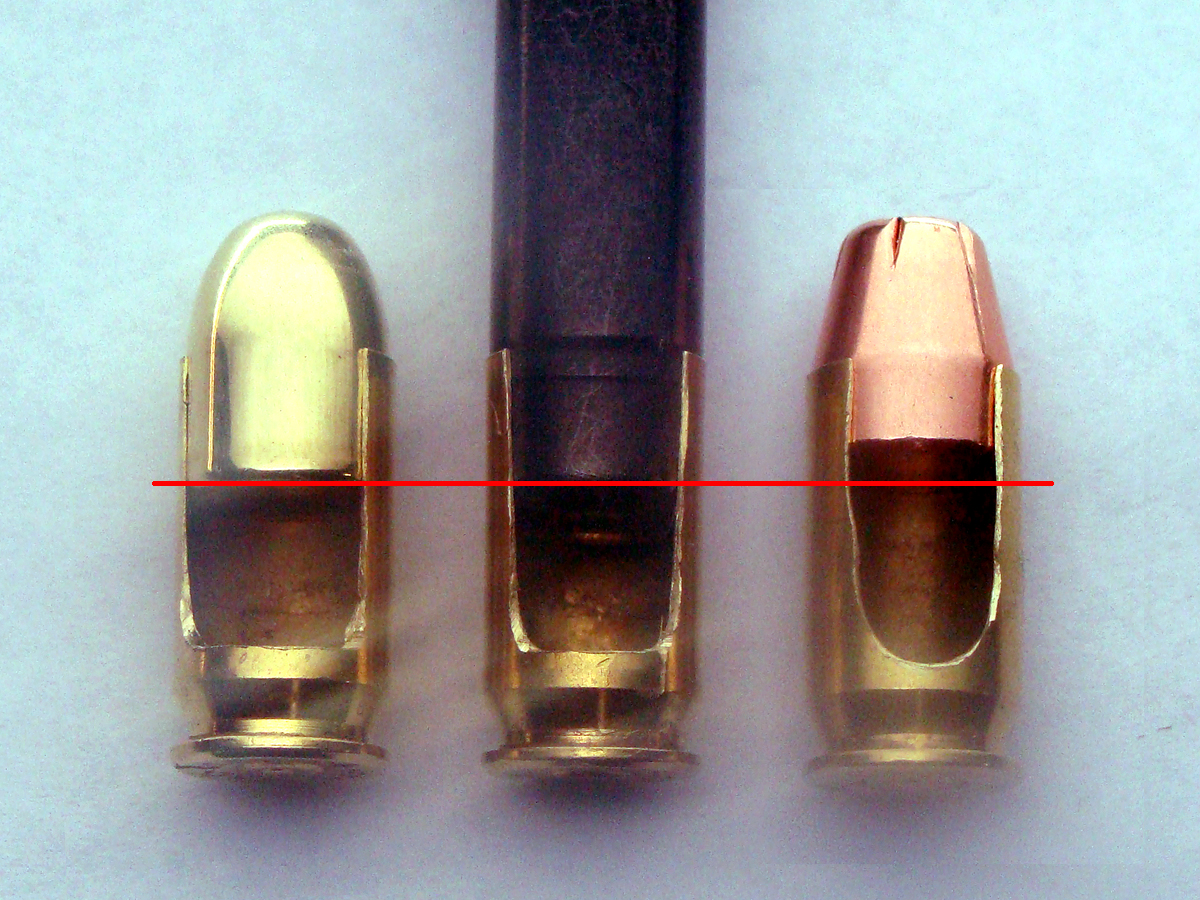

The potential for setback increases when you load a bullet that is significantly shorter than the bullet for which the expander die was designed. Figure 3 shows cutaways of three .45 ACP cases - the case on the left shows a 230gr FMJ bullet seated to the proper depth, the case in the center shows the expander mandrel fully inserted, and the case on the right shows a properly seated 185gr JHP bullet. The line across the three cases shows the depth to which the expander mandrel was inserted. You can clearly see that the while the expander depth is ideal for the 230gr bullet, it reaches deeper into the case than is necessary for the 185gr bullet, making setback very likely when using this bullet.

There are a couple of ways to fix this problem - neither of which is very simple. One way is to purchase additional expander die mandrels and have them machined to optimize them for a shorter bullet. This is an option for dies made with removable mandrels (RCBS, Lee, Lyman) but will not work with the expander dies made by Hornady which do not have a removable mandrel.

Another way is to back out the expander die so that the mandrel enters the case only to a depth equal to the seating depth of the bullet. This will leave the case mouth unflared, so an additional die - called a Universal Case Expanding Die (made by Lee) - should be used to flare the case mouth.

The Lee Universal Case Expanding Die is equipped with two cone-shaped inserts that allow the die to flare the case mouths of any caliber from .22 to .45. This die only flares the case mouth - it does not have an expander mandrel.

In some instances, you may be able to simply use the Universal Expander Die in place of the expander die that came with your set. Before doing this, you should run some test rounds and gage them to ensure that they'll chamber in your pistol. On thicker-than-normal brass, the extra force required to seat a bullet in a flared but not expanded case can cause the case to bulge during seating.

Some reloaders attempt to eliminate setback by applying additional taper crimp. While over-crimping may alleviate setback, it can cause other serious problems including case bulging and headspace problems.

Your pistol is causing it

When your pistol's slide moves forward to chamber a round, the nose of the bullet strikes the feed ramp on the barrel. This is when setback

occurs. If your cartridges "pass" the bench test but experience setback when chambered, it's possible that your pistol is a contributing

factor. A rough finish or improper angle on the feed ramp can contribute to (or even be the main cause of) setback. A good way to

determine if your pistol is the culprit is to check for setback with factory ammo in your handgun, and also to retest your rounds in another pistol

(or pistols) of the same caliber. If the setback goes away when you try your rounds in another handgun, or if you see setback with factory

ammo, then your pistol is a likely cause. You should have it inspected by a qualified gunsmith.

Your dies are out of spec

This is an unlikely cause, but if you are using a set of dies for the first time, and your cartridges fail the bench test, it's worth spending

a few minutes to check the dies (I've ended up with three sets that were out of spec in the last ten years). Run a case through the

sizing die and measure the inside diameter. It should be no larger than 0.002" under the bullet diameter. In other words, if

you're loading .45 ACP with a 0.451" diameter bullet, the inside diameter of the case should measure no larger than 0.449". Next, run

a sized case through your expander die and measure the inside diameter. Again, the ID should be no larger than 0.002" under the bullet

diameter. If the dies are out of spec, there's no easy way to fix them. Contact the manufacturer for a replacement.

Your bullets are undersized

This is another unlikely cause, but it can happen. Measure the diameter of a sample of your bullets and ensure that they're in spec.

If you're using plated bullets, or jacketed or cast lead bullets from a questionable source, the bullets themselves could be too small.

Factory Ammo

So, how do the ammo manufacturers prevent setback? One way that manufacturers prevent setback is to load over a powder charge that completely

fills the case (or even over a slightly compressed powder charge). By doing this, the powder itself acts as a stop to prevent the bullet

from setting back. Reloaders can sometimes do this too with careful powder selection.

Also, if you look at sides of the cases for some "personal defense" ammo, you'll notice a feature on the case that looks something like a cannelure. This indentation is formed into the case at a point level with the bottom of the seated bullet; its purpose being to act as a mechanical 'stop' to prevent the bullet from setting back during repeated chamberings. This feature requires an extra manufacturing step, and is not usually found on bulk-pack "practice" ammo. It's one of the reasons why self defense ammo tends to be more expensive than plinking ammo.