09 APR 2022

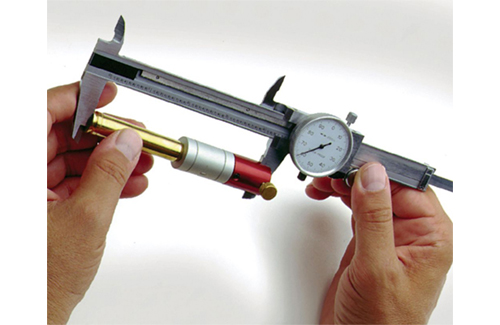

Help! My Round Won't Chamber

This article explains why proper technique and careful component selection are essential for making ammo that will feed reliably.

09 APR 2022

This article explains why proper technique and careful component selection are essential for making ammo that will feed reliably.

05 APR 2022

Not all bullets are created equal. This article highlights why the details matter when selecting components.

01 APR 2022

This is the second installment in a series of articles on case sizing. This time, we'll cover neck sizing of bottleneck rifle cases.

28 MAR 2022

This article describes the process of resizing bottleneck cartridge cases. Setting up the sizing die for a bottleneck case requires a higher level of precision than for straight-walled cases, and the quality of your setup has a much bigger impact on safety, accuracy, and brass life.

27 MAR 2022

Resizing (also known simply as 'sizing') is perhaps the most important step in case preparation. Returning the case to its original factory dimensions (or the correct dimensions for your firearm) allows you to make ammunition that is reliable, safe, and accurate. This article explains how to do it right.

26 MAR 2022

Bullet setback is an undesirable condition where mechanical forces acting on a loaded cartridge cause the bullet to be pressed back into the case (usually during chambering). This article discusses the causes and remedies for setback.

24 MAR 2022

The only reusable part of a fired cartridge is the case. This is fortunate for the reloader because the case is the single most expensive component. Also fortunate is the fact that there is plenty of brass lying around for the taking at just about every range. This article explains what to load and what to leave.

21 MAR 2022

As an instructor, there is one experience in particular that I find truly frustrating:

When I have to reward a really good question with a very bad answer. For example, when a participant in a reloading class asks,

"How many times can a case be reloaded before it must be scrapped?"

The correct (but unhelpful) answer is, "It depends."

20 MAR 2022

The .45 ACP has a reputation for case longevity that borders on mythical. "You can load it until you lose it" is just one phrase commonly used to describe the durability of this caliber. Is it true? Let's find out.

17 MAR 2022

Start low, work your way up, and watch for pressure signs.

This mantra has been repeated - ad nauseum - by every reloading instructor and author since the first shooter reloaded

the first cartridge, but it is still the most sound advice one can give to somebody working up a load. This article

will describe some of the most common pressure signs.

15 MAR, 2022

The only part of a cartridge that can be reused is the spent brass case. The first step in preparing a case for reuse is cleaning it. You need to clean the cases so that they can be easily inspected and will not transfer harmful debris to your dies. There are many ways to clean your cases, but this article will concentrate on the most common method: Dry tumbling.

13 MAR, 2022

Wet tumbling uses an actual tumbler, similar to the kind that were originally designed for polishing rocks along with stainless steel tumbler media. As the drum rotates, the cases and media ride up the sides of the tumbler until gravity causes them to fall back down to the bottom of the drum. The cases rub against each other and the media, which removes all of the fouling and thoroughly polishes the cases inside and out.

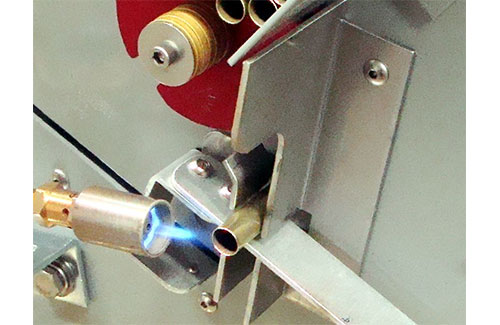

3 MAR, 2022

The word "anneal" means "soften". In the context of cartridge reloading, it means to take a case with a neck that - due to repeated use - has become hard and brittle and prone to failure, and make it (the neck) malleable again so that the case can be reloaded a number of additional times. This article explains the process.

1 MAR, 2022

300 AAC Blackout cases can be formed from trimmed and necked down (yes, "down" - we'll explain later) .223 parent cases. Given the ready availability of .223 brass, many reloaders find it more economical to form their own .300 Blackout brass. This article will examine that process, which consists of four or five steps depending on how you decide to trim.

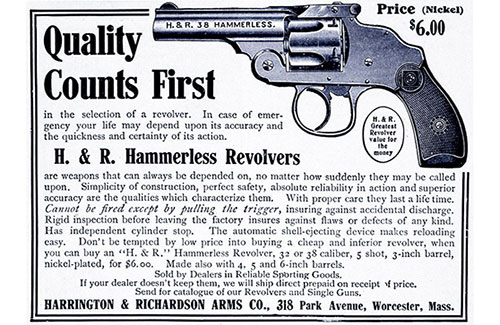

25 FEB, 2022

A while back I acquired a Harrington & Richardson 5-shot 3" hammerless, top-break revolver chambered in .32 S&W. This caliber is sometimes (incorrectly) referred to as .32 "Short" to differentiate it from the better-known-and-descriptively-named .32 S&W Long. My particular revolver was made between 1896 and 1898, and was designed to shoot black powder cartridges. This is where it gets tricky...