In another article, I wrote about forming .300 Blackout cases from .223 brass. At the time, I briefly looked up some load data for the 300 BLK on the Hodgdon website, and saw that there was a load listed for Hornady 110gr bullets and Hodgdon H110 powder. I already had a fresh 8lb jug of H110, so I made a metal note to pick up some Hornady 110gr bullets when I was ready to start loading.

During a visit to Cabela's, I noticed a few boxes of Hornady .30 Cal 110gr rifle bullets on the shelf. Remembering the load from the Hodgdon site, I bought them (even though at the time I wasn't specifically shopping for components). That turned out to be a mistake.

The lesson here is, "Always double-check the data before you buy components", because when I looked up the load later on, I realized I had the wrong bullets. The Hodgdon site had load data for Hornady 110gr V-Max bullets (Part # 23010); whereas I bought the 110gr Varmint SP bullets (Part# 3010) instead.

No big deal, right? As long as you follow the golden rule of, "Start low, work up slowly, and watch for pressure signs", you can use the data for a similar bullet in the same caliber and get satisfactory results almost all the time. Unfortunately, as (bad) luck would have it, this was not one of those times.

In addition to the Varmint SP bullets I mistakenly bought, I was able to later obtain two boxes of the V-Max bullets that are specified in the Hodgdon load data. I decided to load both types and compare the results.

Although the V-Max and Varmint SP bullets are both 110 grains and both made by Hornady, they are not the same exact shape. Including the plastic tip, the V-Max bullet is longer than the lead-tipped Varmint SP (see Figure 1), with a longer ogive. I set the cartridge overall length (C.O.A.L.) based on the longer V-Max bullets so that the internal case volume of the loaded rounds would be greater (and the pressure lower) for the shorter Varmint SP bullets.

I loaded five rounds of each bullet at each of five different charge weights (50 rounds total) and hit the range.

For testing, I used an AR-15 with a 16" Wilson Combat 1:8" twist match-grade barrel, at 100 yards, from a sandbag rest, with a 10X scope. Only the two heaviest charge weights reliably cycled the rifle, so it looked like I was going to have to load these a bit on the hot side. This was not a problem as there were no signs of excessive pressure with even the heaviest charge weight with either bullet.

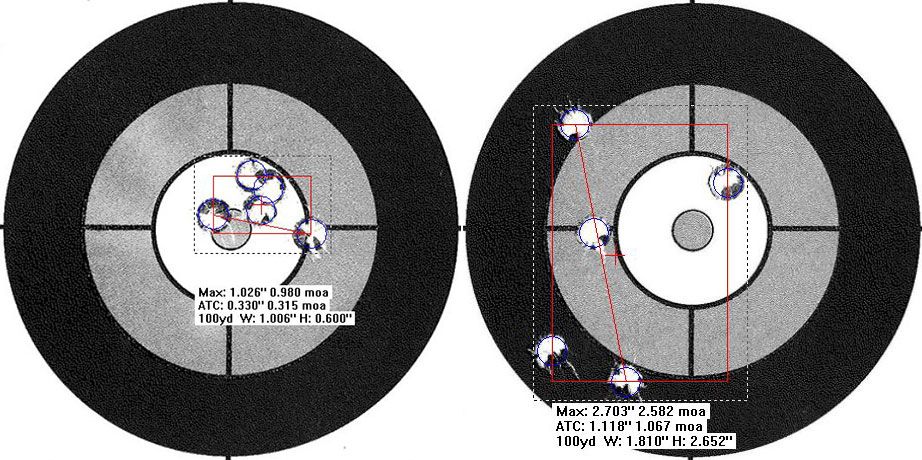

Curiously, there was a very distinct difference in group size between the V-Max and Varmint SP bullets regardless of the charge weight (the best groups from each are shown in Figure 2 below).

The best 5-shot group with V-Max bullets was .98 MOA, with an average group size of 1.15 MOA. The best group with the Varmint SP bullets was 2.58 MOA, with a disappointing average of 2.77 MOA" for the five groups.

This was surprising because it was an across-the-board trend. I would've expected that at least one of the Varmint SP groups would be as tight as one of the V-Max groups, but even the worst V-Max Group was tighter than the best Varmint SP group. Something besides charge weight was the cause.

I decided to try loading some more of the Varmint SP bullets, and varying the cartridge overall length (C.O.A.L.) in an attempt to tighten up the groups. For the "low" end of my test, I figured I'd set the C.O.A.L. to the length specified by Hodgdon for the V-Max bullets, minus the difference in length between the V-Max and SP bullets. At this length, the loaded Varmint SP rounds would have the same internal case volume as the V-Max rounds. For the high end of the length, I wanted to seat the bullets about 0.010" away from the rifling lands.

Normally, I would measure the distance to the lands using the bullet, the Hornady Overall Length gage, and a Hornady modified case, but I didn't have a modified .300 BLK case (and I didn't want to wait for one), so I employed another trick.

I took a .300 BLK case fired from my rifle and thoroughly cleaned the inside of the neck with soap, water, and a brush. I needed to get it clean enough so that glue would stick to it. Working quickly, I squirted a dab of hot glue into the case neck, partially seated a bullet, pressed the dummy round into the chamber of my rifle, and closed the bolt. I waited 30 seconds for the glue to cool, and then carefully extracted the test round.

Since the bullet was only partially seated when the test cartridge went into the chamber, the bullet contacted the rifling. When the test cartridge was fully seated and the bolt closed, the rifling in the barrel actually finished seating the bullet (this only works with a fired unsized case). The glue keeps the bullet in the case during extraction. By measuring the "finished" test cartridge, I could determine the C.O.A.L. at which the bullet would hit the lands. I wanted my longest loaded round to be 0.010" shorter than this.

To double-check my measurements, I loaded a dummy round in a resized case with a C.O.A.L. that put the bullet 0.010" off the lands, loaded it into a magazine, and dropped the bolt to chamber it in the rifle. If the bullet was really 0.010" short of the lands, I would see no engraving from the rifling on the bullet when the round was extracted. When I extracted the round, I found no rifling marks on the bullet, but I did find the real cause of the poor groups from these bullets.

Figure 3 shows some dummy rounds made with each bullet that have been chambered and extracted from the rifle. Notice that the tip of the Varmint SP bullet shows significant deformation from when it forcibly contacted the feed ramps in the barrel, while the V-Max bullet is virtually unscathed.

This explains the difference in group size, and possibly why Hodgdon did not include data for this particular bullet. I tried chambering another dummy round with the C.O.A.L. set at the minimum, and the tip deformation was not quite as bad as on the longer round, but was still significant.

I did some research online and found a couple of other reloaders that had similar experiences. One did further experimentation and found that a C.O.A.L. about 0.150" shorter than my minimum produced rounds that fed reliably with no bullet tip deformation. Loading that short would likely require a reduction in charge weight to avoid an overpressure condition. Since my rifle did not cycle reliably with lighter charge weights, I decided not to try it. I'll use the remaining Varmint SP bullets for a different application.

It's very common for reloaders to use components for which there is no specific published data. For example, I have yet to see any published data for the brass-jacketed handgun bullets that I use all the time. As long as the bullet is a more or less "standard" shape and weight, "close enough" is usually good enough, and you can use the data for a similar bullet from another manufacturer.

However, every reloader should remember that "usually" is different than "always", and whenever you're loading without specific data for your components, you should take a little extra time to verify that everything is performing as it should, and keep your batches small until you're sure that you won't be wasting a lot of components.