The previous article described how to clean your brass cases prior to reloading using a vibratory bowl cleaner and dry media. This month, we'll take a look at wet tumbling with stainless steel media (and also without stainless steel media).

The Equipment

Unlike dry 'tumbling' which uses a vibratory bowl cleaner, wet tumbling uses an actual tumbler, similar to the kind that were originally designed for polishing rocks.

The tumbler consists of a re-sealable watertight drum, a frame with rollers on which to place the drum, and a motor to rotate the drum at 40-60 RPM. The speed is

important - too fast and centrifugal force will cause the cases and media to cling to the sides of the drum with virtually no cleaning action whatsoever. Too slow,

and the cleaning process is inefficient and extremely time consuming.

As the drum rotates, the cases and media ride up the sides of the tumbler until gravity causes them to fall back down to the bottom of the drum. The cases rub against each other and the media, which removes all of the fouling and thoroughly polishes the cases inside and out.

Notice the hexagonal shape of the body of the drum in Figure 1. This shape causes the cases and media to tumble around inside the drum as it runs. If the drum was perfectly round, the cases and media would just slide along the bottom of the drum as it rotates, without the tumbling action that does most of the cleaning. Tumblers with round drums (such as the one shown in Figure 2) feature internal baffles similar to (but smaller than) the baffles inside the drum of a clothes dryer.

Tumbler capacity is a function of the size of the drum, and the amount of weight that the tumbler motor and drive mechanism can reliably rotate. Tumbler capacity is usually specified in pounds. The Thumler's Model B tumbler in Figure 1 has a 15 pound capacity. This might sound like a lot, but the 15 pound capacity includes everything - water, media, and brass - that goes into the tumbler. With a gallon of water (8 pounds) and 5 pounds of media, there is room for only 2 pounds of brass. This translates to about 140 .223 cases.

Larger tumblers, such as the one the one in Figure 2 made by Biggdawg Tumblers of Waverly, Iowa (www.biggdawgtumblers.com) , are available that can handle over 20 pounds of brass and 25 pounds of media per run.

The Media and additives

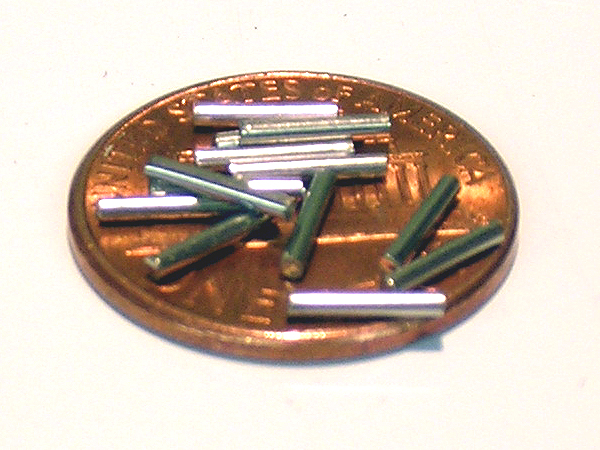

Wet tumblers use stainless steel media. The preferred media is 0.040" diameter by .250" long, 300-series stainless steel pins. The pins are smooth; they

will not erode or work-harden the brass, and they can be reused indefinitely. At nearly $8 per pound, the stainless media is significantly more expensive than dry media.

The instructions that come with your tumbler will specify the amount of media required, but for best results, use at least 1.2 pounds of media for every pound of cases.

The cleaning action is greatly enhanced by adding a few tablespoons of regular dish soap to the tumbler, along with 1/2 teaspoon of a dishwasher water-softener called Lemishine (available online and at Target). Lemishine is a form of citric acid that removes hard water deposits from dishes. In your tumbler, it helps to make the brass ultra-shiny. You can tumble without Lemishine, but your brass won't get as shiny. Do not add more than 1/2 teaspoon because it will turn your brass pink. This doesn't weaken the brass, it just makes it funny looking.

The Process

Before tumbling, you should decap your brass. If you do not remove the spent primers before tumbling, the media will stick inside the flash holes, and

wedge into the primer anvils. You'll discover this when you start breaking decapping pins during resizing (sadly, I learned this through experience).

Removing the primers will also allow the media to clean the flash holes and primer pockets, and cases without primers drain more effectively after tumbling.

To clean your brass, simply fill the tumbler drum with the appropriate amount of water, add the soap, Lemishine, media, and decapped brass. Then install the cover,

place the drum on the tumbler frame, and run it.

After about 3 hours, the brass will come out cleaner than by any other method. The cases will be clean and shiny inside and out; including the primer pockets. After wet tumbling, your brass will look new. After tumbling, you should remove the cover from the drum and rinse the brass and media thoroughly with clean water. This will remove all of the residue, soap, and additives.

Separating the media from the cases can be tricky. Because of surface tension, the stainless steel pins want to stick to anything wet. The easiest way to separate the pins from the cases is to use a regular cage-type media separator (like the RCBS model shown in Figure 4). Simply fill the bottom tub of the media separator about halfway with hot water, then place your cases and media into the media separator cage, and crank it the same way you would as if you were separating dry media from the cases. The pins will fall out of the cases and sink to the bottom of the separator.

When all of the pins have been separated, pour out as much water as you can, and dump the media back into the tumbler drum for storage. If you're going to be using the tumbler frequently, there's no need to allow the media to dry - it won't rust. However, if you're not going to use the tumbler for an extended period of time, it's probably better to allow the media to dry before sealing up the drum.

Tumbling Without Stainless Steel Media

You can wet tumble your brass without stainless media. The benefit of this is that you do not have to decap the brass first, and you can tumble more cases each run because you

don't have to worry about the weight of the media. The downside is that the inside of the cases will not be cleaned (which is not really necessary anyway) and it takes a little longer.

I mostly wet tumble without media and Lemishine. Super clean cases are over rated. I use media and Lemishine when I plan to sell off the brass because it looks nicer.

Advantages

Wet tumbling with SS media provides several benefits when compared to dry tumbling:

Super clean brass - I was pleasantly surprised the first time I cleaned cases using this method. The brass came out spotless, and blindingly shiny. Even heavily

tarnished cases that would not get clean through several cycles of dry tumbling came out looking new.

You can eliminate a tedious hand operation - If you normally clean your primer pockets with a primer pocket brush, you will be pleased to find that you can put that tool on the shelf for good. Wet tumbling leaves the primer pockets even cleaner than the manual method.

No more toxic dust - One of the drawbacks of dry tumbling is that it can produce dust that is laden with toxic lead styphnate from the primer residue. The dust becomes airborne during tumbling and while separating the dry media from the cases. By wet tumbling, you avoid this inhalation hazard entirely, because no dust is generated.

It cleans the same way every time - A wet tumbler with stainless steel media will always clean the cases in the same amount of time, unlike dry media that requires an increasingly longer tumbling cycle as the media gets dirty.

The costs are lower over the long term - Unlike the corncob or walnut media used in dry tumbling, the stainless steel pin media (if you use it) employed for wet tumbling does not ever have to be replaced. In addition, the tumblers themselves are more durable than vibratory bowl cleaners, and will last much longer.

Drawbacks

The old saying, “There's no such thing as a free lunch" applies to wet tumbling. To realize the benefits outlined above, you'll have to be willing to deal with the

following:

There are higher startup costs - This can be a problem for reloaders on a budget. On a capacity-to-capacity basis, a wet tumbler costs about twice as much as a vibratory bowl cleaner.

The media for wet tumbling is also significantly more expense - $10 per pound for stainless steel as opposed to $0.50 per pound for corn cob. You will recoup this

investment in the long run, but it won't do you any good if you can't afford it to begin with.

It adds two additional reloading steps - Instead of decapping while you resize, you will need to decap your cases as a separate step prior to wet tumbling.

Also, as the name implies, when you wet tumble cases, they come out wet. You'll need to dry the cases prior to reloading. This is not particularly difficult -

you can simply spread them out on a towel and allow them to air-dry. The process can be sped up by using a fan to circulate air over the cases as they dry.

During the summer, I found that the cases dry very quickly if I spread them out on a table outside in the sun. You can also place the cases into a warm oven to dry them, repurpose a food dehydrator,

or buy one of the commercially available case dryers (which is nothing more than a repurposed food dehydrator).

Final thoughts

If you'd like to try this method of case cleaning but do not want to spend the money to buy a tumbler, Google “Home Made Wet Tumbler". You will find dozens of ingenious

hobbyist-built devices made out of everything from treadmill parts to discarded clothes dryers. If you're handy, you might be able to build your own wet tumbler from

junk you have lying around your garage. For large batches of 9mm, I use a Harbor Freight cement mixer.